Owning or working in the pharmaceutical industry, it is important to understand the pharma quality audits & inspections. From raw material to packaging products, every step must follow the strict guidelines to protect patient safety, customer trust, and gain a customer satisfaction ratio. But pharma quality audits and inspections always bring stress. So in this article, we will explore the Understanding Pharma Quality Audits & Inspections Simplified.

When talking about an audition in simple terms, it is regarded as the inspection of some systems and ensuring the pharmaceutical company follows the specific requirements of the intended use.

Key Stats Of The Indian Pharmaceutical Sector

According to Wikipedia, the pharmaceutical industry in India is valued at around US$50 billion in FY 2023-24, and it is estimated to grow $130 billion by 2030.

What are Quality Audits In The Pharmaceutical Industry?

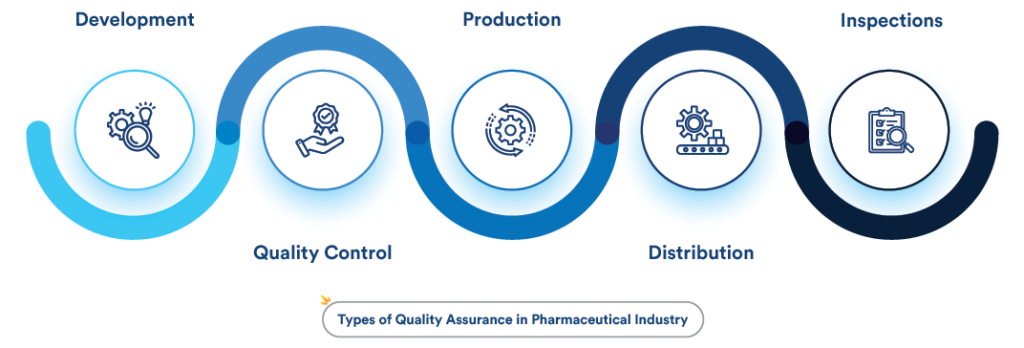

In the pharmaceutical industry, the quality checks and audits are regarded as virtual means for evaluating compliance with various objectives as defined by the dedicated quality system. Because quality audits working in the pharmaceutical sector ensure the product’s continuous improvement by offering relevant feedback to the management.

Why Pharma Quality Audits Matter In The Pharmaceutical Industry?

The pharmaceutical or healthcare products are not for manufacturing or use without audits or inspections; they impact millions of people every single day. That’s why continuous auditing matters in the pharmaceutical facility. Various products such as tablets, syrups, injectables, and drug medicines are manufactured. Even a minor mistake can spoil the medical products or recalls. That’s why regular auditing matters to meet with highest quality standards

Regular quality audits ensure:

- Continuous improvement of quality systems

- Reliable and safe manufacturing processes

- Accurate, complete, and traceable documentation

- Compliance with global regulations

- Early detection of deviations and risks

The strong regulatory programs not only maintained the product integrity but also enhanced the company’s reputation as per credibility.

Pharma Quality Audits Are Basically Two Types Of Audits That Are Conducted.

- Internal audit: these are the most essential for ensuring regulatory compliance and pharma standard quality checks, and operational efficiency. Internal audits are typically performed in inventory management, research or development, and financial audits. Internal audits’ main goal is to identify the hazardous health risks, potential issues, or non-compliance with GMP standards. Regularly, internal auditing helps to maintain the integrity of clinical trials, product safety, and organisational effectiveness.

- External audits: in the pharmaceutical industry, the external audits focus on identifying or verifying under the GMP, GCP, and GLP to ensure to meet with regulatory compliance standards are met. It helps to identify the process of and the evaluation of the company’s manufacturing process.

- Regulatory inspections: Pharmaceutical authorities, FDA & EMA, perform regulatory compliance with adherence to GMP, GCP, and GLP inspection routine for pre-approval.

What Are The Key Benefits Of Pharma Quality Audits & Inspections?

| Benefit | Explanation |

| Regulatory Compliance | Companies with quality checks and audits stay on track with GMP, GCP, and GLP by doing regular audits by inspecting the manufacturing process and ensuring it meets and working with standard agencies FDA, EMA, and WHO. |

| Identify Risks Early | Auditing has main benefits in the pharmaceutical industry; it actually catches every problem easily. Whether it’s documentation errors, raw material errors, or process deviation audits. |

| Enhance Product Quality | Regular audits enhance operational efficiency and allow manufacturers to track testing to ensure quality procedures are followed. This keeps products consistent, purest, and safest, and enhances patient outcomes. |

| Strength Quality Management | Auditing helps to show the company’s working with SOPs, CAPA, or it helps to reduce errors or keep the biopharma industrial system effective and compliant. |

| Enhances Operational Efficiency | Internal and external audits easily identify the errors and help pharmaceutical companies for smooth operations or less raw material wastage. |

| Enhance Customer Confidence Or Regulatory Compliance | Proper audits and inspections enhance brand reputation and the company’s seriousness about safety for clients and patients. |

Why Choose Lifevision Healthcare For The Best Pharma Quality Products?

In the Indian pharmaceutical sector, Lifevision Healthcare is the leading and most trustworthy pharma supplier. This pharmaceutical company offers you high-quality pharmaceutical products that meet global quality standards. Lifevision Healthcare follows GMP, GCP, and GLP guidelines for making every batch undergo proper inspection and receive precise care.

They focus on regular audits and inspecting the guaranteed process by focusing on innovation or continuous improvement. That’s why most of the doctors, hospitals, and patients trust LifeVision. It also provides pharma third-party manufacturing service for starting their own business. They easily Understanding Pharma Quality Audits & Inspections Simplified.

FAQ’s about Understanding Pharma Quality Audits & Inspections Simplified

Q.1 Who does the pharma quality checks and audits?

A: All of the pharma quality checks are done by internal QA teams and verified authorities.

Q.2 What are the best times for audits and inspections of the pharma industry?

A: The best time for routine operations is during manufacturing or ingredient mixing.

Q.3 Do quality checks enhance my brand reputation?

A: Absolutely, quality checks ensure trust and reputation.

Q.4 What are the necessary documents required for quality checks?

A: You need SOP, CPAC, and all the audit reports for quality inspection.

Call Us: 8062750200

Call Us: 8062750200 Contact Us

Contact Us